62nd Year of Education & Service

College of Agricultural Engineering & Technology / Processing & Food Engineering / Faculty

Name : |

Dr Gurnaz Singh Gill |

Designation : |

Scientist |

Office Phone : |

0161-2401960-384(Ext) |

Mobile : |

9876800696 |

Email (Office) : |

gurnazgill@pau.edu |

Research Areas : |

-- |

Researcher ID's : |

-- |

College of Agricultural Engineering & Technology / Processing & Food Engineering / Home

The Department of Processing & Agricultural Structures came into being as a result of trifurcation of the erstwhile Department of Agricultural Engineering in the college of Agricultural Engineering with effect from Dec.1974. Since its beginning the Department has been engaged in teaching, research and extension activities primarily in the field of Processing & Agricultural Structures. However in order to cater to the changing scenario of Indian agricultural, additional PG programmes in the field of Sugar Engineering (M.Tech.) & Agro Industrial Processing (M.Tech. & Ph.D) were started during the year 1991-1992. In order to prepare trained manpower, in the light of global competition due to WTO, GATT etc., the UG & PG curriculum of this department has been further reviewed & upgraded to bring about uniformity of the same throughout the country. As such the name of Department has been changed to Processing & Food Engineering in a meeting held on 13.11.03 in college committee room & notification for the same was issued vide CAE 15551-70 dated 11.03.04. Consequently, the PG programme has also been modified to M.Tech. & Ph.D. in Processing & Food Engineering discipline instead of prevalent programmes.

College of Agricultural Engineering & Technology / Processing & Food Engineering / Head of Department

Name : Dr. Tarsem Chand Mittal

Address : Department of Processing and Food Engineering

Office : 0161-2401960-79 Extn. 384, Ext-322

Phone : 9779900640, 7009367074

E-Mail : hodpfe@pau.edu

Brief Introduction

Dr. Tarsem Chand Mittal is B.Tech. (Agricultural Engineering) and Ph.D from PAU Ludhiana while he did his M.Tech (Post Harvest Engineering) from IIT, Kharagpur. He joined PAU in July 1995 as Assistant Extension Engineer. Since joining PAU, he has been actively involved in research and teaching activities although his main emphasis was in extension activities related to processing and value addition of farm produce, especially the durable crops. He has been instrumental in providing technical guidance to the farmers/ small entrepreneurs for setting up of agro processing complexes (APCs), turmeric processing setups and other units related to value addition of farm produce. Till now he has coordinated more than 150 training courses in the areas of agro processing, storage of produce and entrepreneurship development in value addition. The technologies such as forced air convective recirculatory solar dryer, hybrid solar dryer, turmeric processing machinery developed by him, have received university reconigition and stakeholders adaptation. He has guided 3 Ph.D and about 15 M.Tech students in their research work. He has to his credit about 40 research publications out of which some are in journals of high repute. He has also published about 50 popular articles for the benefit of farmers. He has brought funds from agencies such as UGC, NABARD, ICAR and other state and central agencies through various adhoc projects. For the PMFME scheme of Ministry of Food Processing Industries, Govt. of India, He is Master Trainer in the area of Grain Processing.

Major Research publications of Dr Tarsem Chand Mittal

- Sharma Pallavi, Sharma S R, Dhall R K, Mittal T Cand Chavan Prasad (2022) Pyramided effects of γ-irradiation, packaging, and low-temperature storage on quality, sensory and microbial attributes of minimally processed onion rings. J Food Process Preserv. https://doi.org/10.1111/jfpp.16305.

- Chavan P, Sharma P, Sharma S R, Mittal T Cand Jaiswal A K (2022) Application of high Intensity ultrasound to improve food processing efficiency: A Review. Foods. https://doi.org/10.3390/ foods11010122.

- Singh Sukhmeet, Gill R S, Hans V and Mittal T C (2022) Experimental performance and economic viability of evacuated tube solar collector assisted greenhouse dryer for sustainable development. Energy 241 https://doi.org/10.1016/j.energy.2021.122794.

- Sharma S R, Mittal T C,Alam M S, Bhardwaj Anamika and Sharda Rakesh (2021) Drying behavior of curry leaves under different drying techniques. Agric Res J 58 (5): 881-87.

- Sharma S R, Sinha Aeshna, Kaur Preetinder and Mittal T C(2021) Recent techniques for the management of postharvest losses and quality preservation of fruits and vegetables: A Review. Agric Res J 58 (6): 941-57.

- Sharma P., Sharma S. R., Dhall R.K., Mittal T. C. and Kumar S. (2021) Variation in quality and acceptability of minimally processed garlic in response to γ-irradiation and packaging during refrigerated storage. Radiat Phys Chem https://doi.org/10.1016/j.radphyschem.2020.109193.

- Gill R.S., Singh S., Hans V.S. and Mittal T.C. (2021) Turmeric (Curcuma longa) drying in natural circulation solar dryer: an experimental evaluation.J Food Proc Eng. https://doi.org/10.1111/jfpe.13765.

- Sharma P., Sharma S. R., Dhall R.K., Mittal T. C.and Bhatia S. (2020) Physio-chemical behavior of γ -irradiated garlic bulbs under ambient storage conditions. J Stored Prod Res https://doi.org/10.1016/j.jspr.2020.101629.Sharma, P., Sharma, S.R., Dhall, R.K., Mittal, T.C. (2020) Effect of γ-radiation on post-harvest storage life and quality of onion bulb under ambient condition. J Food Sci Technol 57, 2534–2544

- Gajbhiye Ankit, Gupta Satish Kumar, Alam Md Shafiq, Sharma S R and Mittal T C(2017) Design, development and performance evaluation of aloe vera leaf gel expulsion machine. J Food Process Engg (doi:10.1111/jfpe.12543): 1-10.

- Selvam T A, Manikantan M R, Chand T, Sharma R and Seerangurayar T (2014) Compression loading behaviour of sunflower seeds and kernels. Int. Agrophys., 28: 543-548.

College of Agricultural Engineering & Technology / Processing & Food Engineering / Thrust Areas

- To strengthen UG and PG teaching programmes to meet challenges in the area of Processing & Food Engineering.

- To conduct need based research in the area of cleaning, grading, drying, packaging, handling and storage of agricultural products and by-product utilization suiting to farmers and food industries.

- To develop and strengthen linkages with the growers/farmers, private and public sector agro processing enterprises, transfer of technology and to provide advisory/consultancy services to promote entrepreneurship.

College of Agricultural Engineering & Technology / Processing & Food Engineering / Faculty

Faculty

| S.No | Name & Designation | E-Mail/Telephone |

| 1. | Dr Gagandeep Kaur Nagra Scientist (Microbiology) |

gagannagra@pau.edu 8360072352 |

| 2. | Dr (Mrs) Gagandeep Kaur Sidhu Principal Scientist |

gagandeep@pau.edu 098158-54300 |

| 3. | Dr Gaganjyot Kaur Scientist (on leave) |

engg-gagan@pau.edu 098781-14400 |

| 4. | Dr Gurnaz Singh Gill Scientist |

gurnazgill@pau.edu 9876800696 |

| 5. | Dr Gurveer Kaur Scientist |

kaurgurveer91@pau.edu 8670670348 |

| 6. | Dr Mahesh Kumar Professor |

mahesh@pau.edu 94786-40539 |

| 7. | Dr Maninder Kaur Scientist |

maninderkaur1@pau.edu 9464673737, 9501987755 |

| 8. | Dr Manpreet Kaur Saini Entomologist |

mksaini@pau.edu 9463150838 |

| 9. | Prof Mohammed Shafiq Alam Principal Scientist (Incharge AICRP on PHE&T) |

ms_alam@pau.edu 094171-88501 |

| 10. | Dr Preeti Scientist |

preetbirwal@pau.edu 9896649633 |

| 11. | Prof Preetinder Kaur Principal Scientist |

preetinder72@pau.edu 9592088335 |

| 12. | Dr Rohit Sharma Scientist |

rohitsharma@pau.edu 098889-97081 |

| 13. | Dr S R Sharma Professor |

sajeevrattan@pau.edu 098722-21839 |

| 14. | Dr Sandhya Senior Scientist |

sandhya-pfe@pau.edu 081464-44522 |

| 15. | Dr Satish Kumar Professor |

satish66@pau.edu 094643-65617 |

| 16. | Dr (Mrs) Surekha Bhatia Principal Biochemist |

surekhabhatia@pau.edu 075080-07942 |

| 17. | Dr Tarsem Chand Mittal Principal Extension Scientist-cum-Head |

tarsem6972@pau.edu 09779900640 |

| 18. | Dr Varsha Kanojia Scientist |

varshakanojia@pau.edu 8349197396 |

College of Agricultural Engineering & Technology / Processing & Food Engineering / Faculty Distinctions

| Name of Award | Number |

| Rafi Ahmad Kidwai memorial prize Award | 1 |

| NRDC Awards | 4 |

| Fellow, ISAE | 4 |

| Team Award, ISAE | 1 |

| Commendation Medal, ISAE | 5 |

| Certificates of Merit, ISAE | 2 |

| Reddy Award | 1 |

| Gold Medal, Institution of Engineering (India) | 8 |

| Fellow, Association of Oil Technologists (India) | 1 |

| National System Award, System Society of India | 1 |

| Tamar Pattar, Punjab Government | 1 |

| State Youth Award, Punjab Government | 1 |

| Commendation Medals, Punjab Chapter of ISAE | 5 |

| Commendation Certificate, Punjab Chapter of ISAE | 1 |

| Certificates and Mementoes, Punjab Chapter of ISAE | 4 |

| PAUTA Award, PAU | 1 |

| Advance Increments, PAU | 4 |

| Award of honour by Association of Food Science Technologist (Punjab Chapter) | 1 |

| ISTE Award | 2 |

| Bhart Jyoti Award and Certification of excellence by India International Friendship Society | 1 |

| Award for guiding M.Tech student by Indian National Academy of Engineers | 1 |

| Who's Who in science and Engineering by Marquis USA | 1 |

| Shiksha Rattan Purskar and certification of excellence by India International Friendship Society | 1 |

| Best ISAE chapter award as a member of ISAE, Pb. Chapter | 1 |

| “BEST POSTER AWARD” at International Conference on ‘Grain legumes, quality improvement, value addition and trade held at Indian Institute of Pulse Research, Kanpur. | 1 |

| Young Scientist Award by Punjab Academy of Sciences, Patiala for excellent/innovative research in the field of allied sciences | 1 |

| Lal Bahadur Shastri Young Scientist Award for Biennium (2007-08), ICAR | 1 |

| “Shiksha Rattan Puraskar” from India International Friendship Society, New Delhi by Governor of Tripura on 7th April 2010. | 1 |

| Innovative Students Project Award, Indian National Academy of Engineering | 1 |

| Who's Who in science and Engineering by Marquis USA | 1 |

| Distinguished services Certificate Awarded by“Indian Society of Agricultural Engineers (ISAE)” | 1 |

| “Kunwar Saxena Bahadur SRDA Award-2011” by Society for Recent Development in Agriculture at International conference held at SVPUA&T, Meerut | 1 |

| Best poster award for paper presented at National Seminar on Sustainable Agriculture and Food Security: Challenges in Changing Climate (SAFS-2012) held during March 27-28 at HAU, Hisar. | 1 |

| 2nd Prize for Poster presentation entitled ‘Modeling gas exchange dynamics of fresh-cut vegetables under modified atmospheres’ presented under Poster Theme Area (D) at International Conference on Sustainable Agriculture for Food and Livelihood Security held at PAU, Ludhiana | 1 |

| Copyright for Computer Software “Expert System for precision computation of Automatic Weather Station data” vide CERTIFICATE NUMBER L-47275/2013, from Govt. of India, Ministry of Human Resource Development, Copyright Office, New Delhi. | 1 |

| Outstanding Poster Appreciation Award for poster presentation ‘Green packaging for foods: An environment friendly perspective’ at Regional Seminar on “Geospatial technology in natural resource management” organized by ISRS at PRSC, Ludhiana | 1 |

| Best Poster Award for the paper entitled, “Changes in biochemical and bioactive compounds of coriander puree by innovative freezing process during storage” presented at 25th Indian Convention of Food Scientists & Technologists “Food-Pro SAI 2016” held at GNDU, Amritsar during November 10-12, 2016 | 1 |

College of Agricultural Engineering & Technology / Processing & Food Engineering / Important Achievements

|

Outstanding Milestones/ Research Evaluation Committee Approved Technologies |

|

|

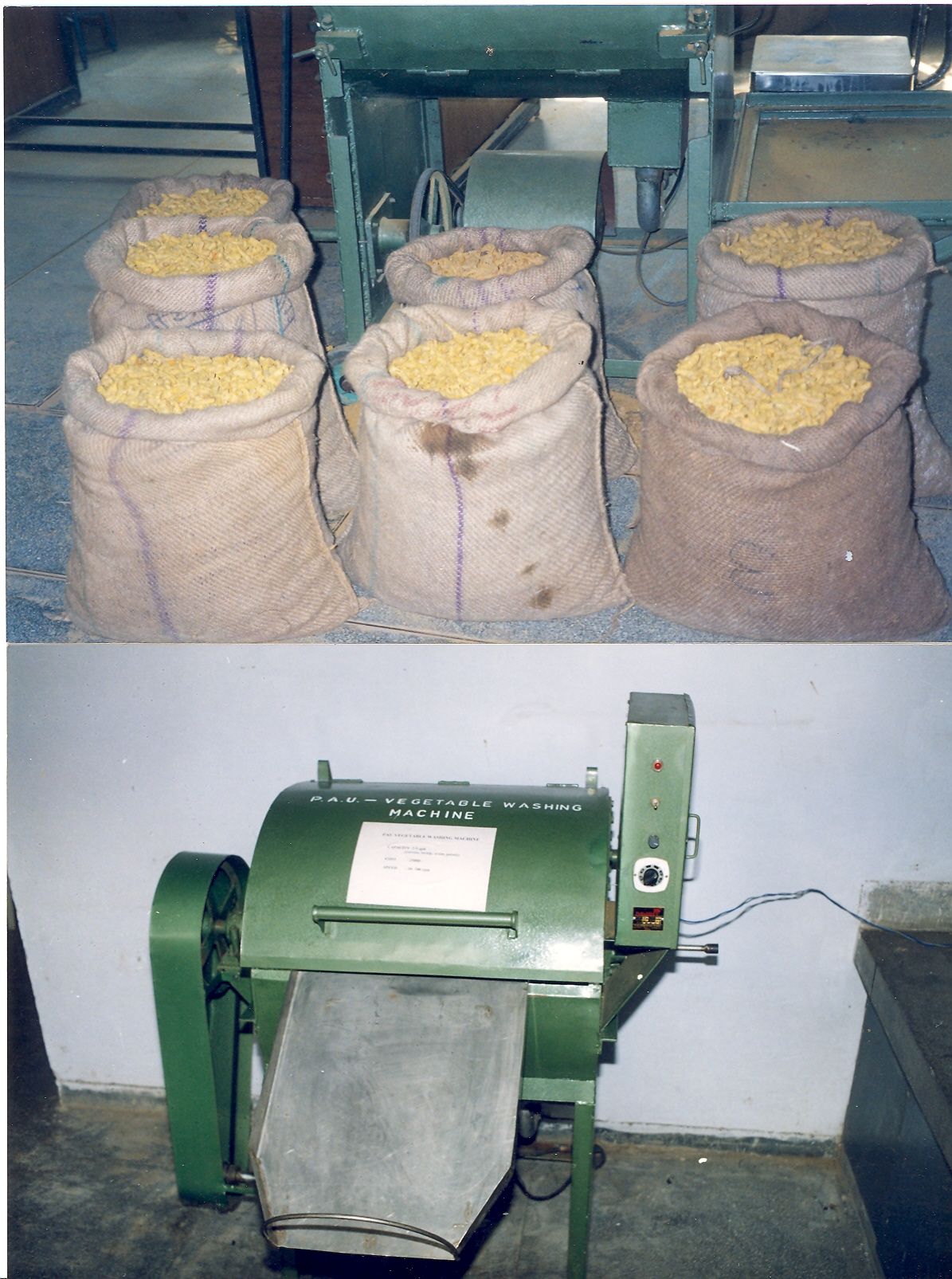

Agro-Processing Complexes: Rural entrepreneurship through suitable agro-processing models/complexes is essential to increase the income of the farmers, provide significant employment opportunities to the rural youth and reduce huge amount of post harvest losses. These include a 5 qtls per hour Atta chakki for whole flour, a mini rice mill processing 250 kg/h, an oil expeller unit processing 100 kg/h, a honey processing unit completing 50 kg/batch in one hour, a spice grinding unit for turmeric and red chilli, a jaggery processing unit handling 10 qtls/h, a feed mill, and a dal processing and packaging unit. The estimated cost of machinery ranges from Rs. 15 to 25 lakh. The department has designed a suitable layout requiring a minimum space of 50 ft X 60 ft to accommodate the machines, although additional open space is needed for vehicle movement. A total electric load of 25 KW is sufficient to operate the machines. Such unit creates employment opportunities for 2-5 individuals in rural areas. |

|

|

PAU Portable maize dryer: A portable maize dryer has been developed as per international norms to dry maize grain from a moisture level 25% to 15% in 8-10 hours. This cross-flow dryer has three pass, indirect type diesel fired heating system to maintain the grain temperature of 45?C for seed and 60?C for commercial purpose. The dryer is capable of drying maize grain @ 1 – 1.5 % per hour consuming max 4 litres/h of diesel initially for 1 hr. A provision of heat recovery from flue gases ensures higher fuel efficiency with reduced diesel consumption of approximately 2 litres/hr later on. The dryer can be operated both with tractor PTO and electricity. One each skilled and unskilled labour is required to operate this dryer. |

|

|

Horticultural Produce Washing Machine: A stainless steel, portable, 1 hp, electric power operated rotary drum type washing machine (1-6 qph, capacity) has been developed to wash a wide range of fruit and vegetables (carrot, potato, radish, turnip, ginger, okra, tomato, spinach, turnip, kinnow and pears). Washing cost is Rs.1-10 per qtl depending on the crop and the model of the machine used. This machine costs Rs. 90,000 and can be used both by the producer and processor. |

|

|

Honey heating-cum filtration Unit: This is a fully mechanized Honey Filtration Unit with separate heating and filtration arrangements having two separate sensors for sensing and controlling the temperature of heating water as well as honey in the main chamber. It consists of two sections; the top heating section and the lower filtering section. In order to have uniform temperature profile throughout the heated honey an electrically operated six fins stirrer stirring the sample at optimum speed as and when required. The filtration section consists of a strainer of 200 mesh size which could be detached for cleaning, a valve for releasing the heated honey to pass through the filtration unit and a pump (operated by 0.5 h.p motor) to flush out the honey at the rate of 10kg/min. The operator is comfortable while working with it. One person is required for its operation. The cost of honey heating-cum-filtration machine is approximately Rs.90, 000 which can process approximately 2 qtls of honey per day. |

|

|

Turmeric washing and polishing machine: Turmeric rhizomes can be mechanically washed as well as polished in a, portable, electric power (1 hp) operated, rotary drum type turmeric washing and polishing machine. The machine when operated at optimum rotational speed for optimum time can wash 2.5-3.0 qph of turmeric rhizomes. At optimum performance parameters, i.e. 40 rpm for 5 min. there is no bruising in turmeric rhizomes, with a microbiological washing efficiency of 91%. The same machine can be used for polishing turmeric with some modifications. The capacity of turmeric polishing machine is 1 qph. The optimum performance parameters for polishing are 40 rpm for 20 minutes at which the desirable olive yellow colour is obtained and the surface becomes smooth. This machine costs Rs. 80,000-1, 00,000/- (and can be used both by the producer and processor). |

|

|

Brick and Sand Store: A simple structure of double wall of bricks, sand and cement of size 1.9 m X 1.3 m and a height of 0.6 m have been developed for domestic storage of fruits and vegetables. This structure has sand in two walls. The sand is kept wet by adding water periodically which is allowed to evaporate causing cooling in the interior chamber. The structure is covered from the top with a net and a wet jute bag is placed over it. Capacity of the structure is approx. 30 to 40 Kg and temperature reduction upto 10-15° C can be achieved. |

|

|

Electric-cum-Battery Heated Uncapping Knife: In order to make the uncapping process more effective an electric-cum-battery heated uncapping knife working both on AC as well as 12 V DC can uncap one frame in 20-22 seconds. Its performance is better in comparison to the conventional knife in respect of ease of operation and timeliness. |

|

|

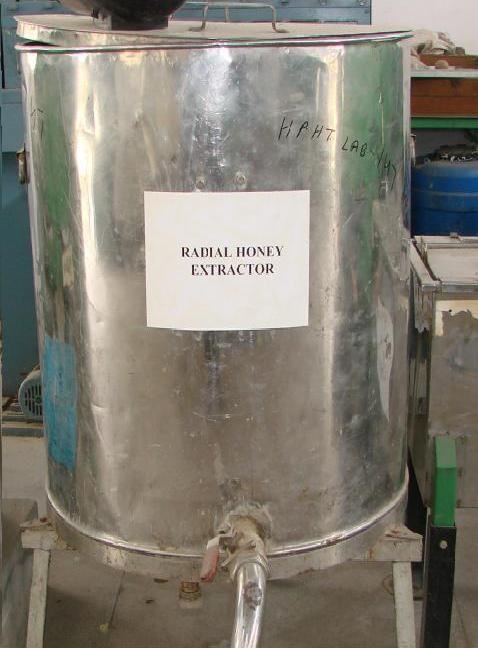

Radial honey extractor: The Power-cum-hand operated eight frame radial honey extractor made up of stainless steel (food-grade) was designed and developed. This works efficiently at 165 rpm with the honey recovery of 192 kg/h. The initial investment is Rs. 50,000 and the running cost is Rs. 11/ q of honey. |

|

|

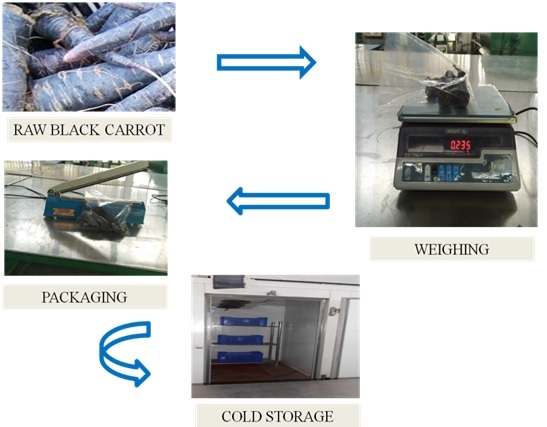

Technology for extending shelf life of fresh black carrot cv. Punjab Black Beauty by Modified Atmosphere Packaging and Storage Packaging of fresh whole black carrot in non-perforated 150 gauge LDPE packages followed by storage at 5oC and 85±5% can extend its shelf life to 21 days for retail marketing.Packaging of fresh whole black carrot in perforated 150 gauge LDPE packages and storage at 10oC and 85±5% can extend its shelf life to 15 days for retail marketing.Storage of unpackaged black carrot at 5± 1oC and 85±5% can extend its shelf life to 12 days for retail marketing. |

|

|

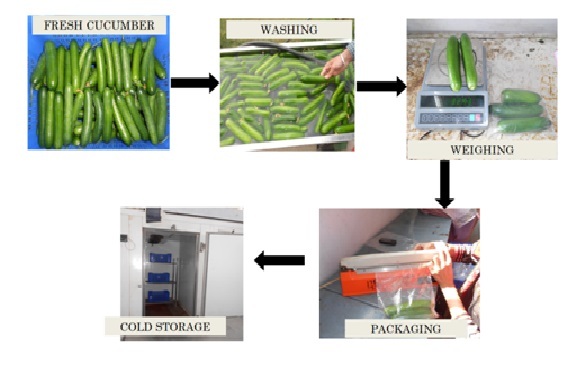

Technology for Enhancing Shelf Life of Fresh Cucumber by Modified Atmosphere Packaging and Storage: Packaging of fresh cucumber in non-perforated 150 gauge LDPE packages followed by storage at 10oC and 85±5% can extend the shelf life of varieties KUK-9, KAFKA, PBRK 4 to 28 days and MULTISTAR to 24 days for retail marketing. |

|

|

Aloe vera leaf gel extraction machine: This machine will cut the processing cost as it’s capable of extracting large amount of gel from aloe vera leaf in small time. It saves lot of labour and can solve the problem of labour scarcity especially in aloe vera gel extraction process. The cost of the aloe vera leaf gel extraction machine is around Rs 35000. The machine is simple in operation, hazard free, made of food grade material and needs 1 hp power for operation and the operational cost per day is also very less. |

|

|

Pilot scale plant for pectin extraction and its process optimization for kinnow and mosambi waste (peel) The developed Pilot scale plant for pectin extraction using chemical method (HNO3/HCl) having capacity of 50 kg/batch of kinnow/mosambi peel yield 14±1 and 18±1% (d.w) pectin from kinnow and mosambi peel respectively. Optimized operational conditions of pilot plant for pectin extraction are pH of solution 2.0, temperature 74°C, extraction time 60 min and pH of solution 1.32, temperature 78.5±1°C, extraction time 60 min for kinnow and mosambi peel respectively.The developed pilot scale pectin extraction plant will be helpful for the budding entrepreneurs/processors dealing in kinnow/mosambi juice processing. |

|

|

Mechanically Ventilated Onion Storage Structure: The structure is made up of angle iron frame and wire mesh. The 1.25 ton onions can be filled by one person in almost 30 minutes while the structure could be emptied in 5 minutes by raising the front sliding gate. In addition to natural ventilation a provision of mechanical aeration has been provided at the base of this storage structure. Total losses in stored onions in the fabricated structure due to all reasons were observed to be 26%. The cost of storage structure is approx. Rs. 10,000/- |

|

College of Agricultural Engineering & Technology / Processing & Food Engineering / Current Projects

New Link

College of Agricultural Engineering & Technology / Processing & Food Engineering / Important Publications

- Aslam Raouf, Alam M S, Ali Asgar, Tao Yang, Manickam Sivakumar (2023) A chemometric approach to evaluate the effects of probe-type ultrasonication on the enzyme inactivation and quality attributes of fresh amla juice. Ultrasonics Sonochemistry, 2:106268doi:10.1016/j.ultsonch.2022.106268. Pp 1-11 (NAAS Rating: 15.64)

- Kaur Maninder, Kumar Satish, Samota Mahesh Kumar and Lalremmawii (2023) Ohmic heating technology systems, factors governing efficiency and its application to inactivation of pathogenic microbial, enzyme inactivation, and extraction of juice, oil, and bioactive compounds in the food sector. Journal of Food and Bioprocess Technology. (NAAS Rating:11.5)

- Wagh Muktabai Dinesh, Alam M S, and Raouf Aslam (2023) Vacuum impregnation of ascorbic acid and calcium lactate improves quality attributes and functionality of white button mushrooms. Journal of Food Processing and Preservation DOI: 10.1155/2023/6728630 (NAAS Rating: 8.61)

- Roy T, Alam M S and Gupta R (2023) Optimization of foaming process for development of modified aloe polysaccharide (MAP) juice and powder using foam?mat drying. Food Science and Biotechnology. https://doi.org/10.1007/s10068-023-01354-6 (Springer Publication) (NAAS Rating: 9.23)

- Kaur Kulwinder, Kumar Satish, Kaur Preetinder, Saini Manpreet Kaur, Singh Arashdeep, Bala Manju and Singh Dhanwinder (2023). Optimization of process parameters for ozone disinfestation of C. Maculatus: Effects on germination, in vitro protein digestibility, nutritional, thermal and pasting properties of mung bean grains. Ozone: Science and Engineering. DOI: 10.1080/01919512.2023.2210615. (NAAS Rating: 8.60)

- Mahajan Kashika, Gupta S K, Sharma S R, Singh Nav Prem and Kanojia Varsha (2023) Evaluation of precooling methods for shelf-life enhancement of pear (Pyrus spp.) fruits under ambient storage. Indian J Agri Sci 93(1):116-18. (NAAS Rating: 6.37)

- Zalpouri Ruchika, Singh Manpreet, Kaur Preetinder, Kaur Amrit, Gaikwad Kirtiraj K., and Singh Ashutosh. (2023). Drying kinetics, physicochemical and thermal analysis of onion puree Dried Using a Refractance Window Dryer. Processes 11, no. 3: 700. https://doi.org/10.3390/pr11030700 (NAAS Rating: 9.35)

- Kaur Gurjeet, Sidhu Gagandeep Kaur and Kaur Preetinder (2023) Moisture sorption isotherms characteristics for shelf-life prediction of peanuts (Arachis Hypogaea L.). Journal of the Science of Food and Agriculture. https://doi.org/10.1002/jsfa.12475 (NAAS Rating: 10.13)

- Kaur Preetinder, Zalpouri Ruchika, Modi Ritika, Param Pal Sahota, Dhillon Tarsem Singh and Kaur Amrit (2023) Development and standardization of processing technique for ready-to-use lab fermented Kanji mix using refractance window dried black carrot powder. Scientific Reports 13, 185. https://doi.org/10.1038/s41598-023-27450-5 (NAAS Rating: 11.00)

- Singh Prastuty, Kaur Gurkirat, Singh Arashdeep and Kaur Preetinder (2023) Starch based bio- nanocomposite films reinforced with montmorillonite and lemongrass oil nanoemulsion: development, characterization and biodegradability. Journal of Food Measurement and Characterization 17, 527–545. (NAAS Rating: 9.01)

- Kaur M, Bhatia S, Gupta U, Decker, E, Tak Y, Bali M and Bala, S. (2023). Microalgal bioactive metabolites as promising implements in nutraceuticals and pharmaceuticals:inspiring therapy for health benefits. Phytochemistry Reviews, 1-31. (NAAS Rating: 13.70)

- Kalsi B S, Singh S, Alam M S, and Bhatia S (2023) Microwave Drying Modelling of Stevia rebaudiana Leaves Using Artificial Neural Network and Its Effect on Color and Biochemical Attributes. Journal of Food Quality, Volume 2023, Article ID 2811491, https://doi.org/10.1155/2023/2811491 ((NAAS Rating: 9.20)

- Singla C, Aggarwal R, Kaur S, Sharma R (2023). Analysis of meteorological parameter changes using Mann-Kendall statistical tests in Indian Punjab. Mausam, 74. 207-216. (NAAS Rating: 6.64)

- Samota Mahesh Kumar, Kaur Maninder, Sharma Madhvi, Sarita, Krishnan Veda, Thakur Julie, Rawat Mandeep, Phogat Bhagyashree, Guru P N (2023) Hesperidin from citrus peel waste: extraction and its health implications. Quality Assurance and Safety of Crops & Foods 15(2): 71-99 (NAAS Rating: 7.67)

- Maninder Kaur, Mahesh Kumar and VP Sethi (2022) Maintaining the freeze thawing characteristics of tomato through development and evaluation of magnetic field assisted freezing system. Journal of Food Processing and Preservation. 00, e16900. https://doi.org/10.1111/jfpp.16900. (NAAS Rating: 8.61)

- Kaur Kulwinder, Kaur Preetinder, Kumar Satish, Zalpouri Ruchika and Singh Manpreet (2022) Ozonation as a potential approach for pesticide and microbial detoxification of food grains with a focus on nutritional and functional quality. Food Reviews International. https://doi.org/10.1080/87559129.2022.2092129 (NAAS Rating: 12.04)

- Ozukum M, Kumar S, Kaur K and Singh A (2022) Effect of microwave drying of paddy on milling characteristics, cooking quality, and microstructure of rice. Acta Alimentaria. DOI: 10.1556/066.2022.00142 (NAAS Rating: 7.0)

- Sharma Pallavi, Sharma S R, Dhall R K, Mittal T C and Chavan Prasad (2022) Pyramided effects of γ-irradiation, packaging, and low-temperature storage on quality, sensory and microbial attributes of minimally processed onion rings. J Food Process Preserv. https://doi.org/10.1111/jfpp.16305. (NAAS Rating : 8.19)

- Chavan P, Sharma P, Sharma S R, Mittal T C and Jaiswal A K (2022) Application of high?Intensity ultrasound to improve food processing efficiency: A Review. Foods https://doi.org/10.3390/ foods11010122. (NAAS Rating : 10.35)

- Singh Sukhmeet, Gill R S, Hans V and Mittal T C (2022) Experimental performance and economic viability of evacuated tube solar collector assisted greenhouse dryer for sustainable development. Energy https://doi.org/10.1016/j.energy.2021.122794 (NAAS Rating: 14.85)

- Tiwari R K, Mittal T C, Singh Sukhmeet, Sharma S R and Rani Sunita (2022) Design and development of solar hybrid distillation system for essential oil extraction from turmeric, J Food Process Preserv. DOI: 10.1111/jfpp.17066 (NAAS Rating: 8.62)

- Tiwari R K, Mittal T C, Sharma S R and Rani Sunita (2022) Effect of the distillation methods on the chemical properties of the turmeric essential oil. J Food Process Preserv DOI: 10.1111/jfpp.17247 (IF: 2.190 and NAAS Rating: 8.19)

- Kaur Gurjeet, Sidhu Gagandeep Kaur, Kaur Preetinder and Kaur Amarjit (2022) Influence of ozonation and roasting on functional, microstructural, textural characteristics, and aflatoxin content of groundnut kernels. Journal of Texture Studies 53, 908-922. (NAAS Rating: 9.94)

- Singh Ramandeep, Kaur Gagandeep and Kaur Gurjeet (2022) Shelf-life Prolongation of Spring Groundnut Pods (Arachis hypogaea L.) using Packaging Systems. Journal of Scientific and Industrial Research, 81: 393-40. (NAAS Rating: 7.07)

- Prasad Chavan, Kaur Gagandeep and Amit K Jaiswal (2022) Performance Evaluation of Mobile Liquid Cooled Thermoelectric Refrigeration System for Storage-Cum-Transportation of Fruits and Vegetables. Foods, doi.org/10.3390/foods11131896: 1-18. (NASS Rating: 10.35)

- Panayampadan AS, Alam M S, Aslam R and Kaur J (2022). Vacuum impregnation process and its potential in modifying sensory, physicochemical and nutritive characteristics of food products. Food Engineering Reviews. https://doi.org./10.1007/s12393-022-09312-4 Pp1-14. (NAAS Rating: 11.76)

- Panayampadan AS, Alam MS., Aslam R., Kumar Gupta S and Kaur Sidhu G. (2022). Effects of alternating magnetic field on freezing of minimally processed guava, LWT- Food Science and Technology doi: https://doi.org/10.1016/j.lwt.2022.113544. (NAAS Rating: 10.95)

- Baldev Singh Kalsi, Sandhya Singh and Mohammed Shafiq Alam (2022) Influence of ultrasound processing on the quality of guava juice. J Food Process Engg; e14163, doi: 10.1111/jfpe.14163 (NAAS Rating: 8.36)

- Aslam R, Alam M S, Kaur J, Panayampadan A S, Dar O I, Kothakota A, and Pandiselvam, R. (2022). Understanding the effects of ultrasound processing on texture and rheological properties of food. Journal of Texture Studies, 53(6), 775–799. (NAAS Rating: 9.22)

- Kaul Shivani, Kaur Kamaljit, Kaur Preetinder and Kaur Jaspreet (2022) Development and shelf-life assessment of Ready-to-Bake frozen potato Paranthas fortified with iron and zinc. International Journal of Food Science & Technology 57, 7214-7221. (NAAS Rating: 9.61)

- Potdar Pratik Pandit, Kaur Preetinder, Zalpouri Ruchika, Ummat Viruja (2022) Convective and pulsed microwave drying of lemongrass (Cymbopogon citratus) shreds: Kinetic modeling, retention of bio- actives, and oil yield. Journal of Food Processing and Preservation 46, e16914. (NAAS Rating: 8.61)

- Zalpouri Ruchika, Singh Manpreet, Kaur Preetinder and Singh Sukhmeet (2022) Refractance Window Drying–a Revisit on Energy Consumption and Quality of Dried Bio-origin Products. Food Engineering Reviews. https://doi.org/10.1007/s12393-022-09313-3 (NAAS Rating: 12.74)

- Sharma Rajan, Bhandari Manisha, Kaur Kulwinder, Singh Arashdeep, Sharma Savita and Kaur Preetinder. (2022). Molecular interactome and starch?protein matrix, functional properties, phytochemical constituents and antioxidant activity of foxtail millet (Setaria italica) flour as influenced during gaseous ozonation. Cereal Chemistry. 99. 10.1002/cche.10559. (NAAS Rating: 8.53)

- Sinha Aeshna, Gill PPS, Jawandha SK, Kaur Preetinder, Grewal SK. (2022) Salicylic acid enriched beeswax coatings suppress fruit softening in pears by modulation of cell wall degrading enzymes under different storage conditions. Food Packaging and Shelf Life 32:100821. (NAAS Rating: 14.75)

- Kaur G and Bhatia S (2022) Radish leaf protein concentrates: Optimization of Alkaline extraction for production and Characterization of an alternative plant protein Concentrate. J of Food Measurement and Characterization. DOI https://doi.org/10.1007/s11694-022-01411-4 (NAAS Rating: 8.43)

- Tak Y, Kaur M, Kumar R, Gautam C, Singh P, Kaur H, Kaur A, Bhatia S , Jha N K, Gupta P K , Amarowicz R (2022). Repurposing Chia Seed Oil: A Versatile Novel Functional Food. J of Food Science, DOI: 10.1111/1750-3841.16211 ,1-22 (NAAS Rating:9.17)

- Kaur G and Bhatia S (2022) Alpha-amylase-assisted extraction of protein concentrates from Raphanus sativus L. leaves. Biomass Conversion and Biorefinery, 1-15. (NAAS Rating: 10.9)

- Preeti B, Ravindra M R, Surendra Nath B and Gajanan Panditrao D (2022). Impact of pulsed electric field treated milk on quality of paneer and khoa. Food Science and Technology International, 10820132221102277 (NAAS Rating: 8.64)

- Solanki Chandan, Gupta S K and Alam M S (2021). Microwave-assisted pre-milling treatments of chickpea (Cicer Arietinum) for higher recovery. Emirates Journal of Food and Agriculture 33(11): 965-971. (NAAS Rating: 7.04)

- Kaur Preetinder, Kaur Kulwinder, Devgan Kirandeep, Kumar Mahesh, Sandhu Kanchan and Kaur Amrit. (2021) Potential of low dose aqueous ozone treatment and packaging to extend quality and shelf-life of green pea pods under cold storage. Journal of Food Processing and Preservation. (NAAS Rating: 8.61)

- Kaur Preetinder, Devgan Kirandeep, Kumar Nitin, Kaur Amrit, Kumar Mahesh and Sandhu Kanchan (2021) Quality retention and shelf-life prolongation of cucumbers (Cucumis sativus L.) under different cool storage systems with passive modified atmosphere bulk packaging. Packaging Technology and Science 1-12. (DOI: 10.1002/pts.2595) (NAAS Rating: 8.55).

- Sharma Rohit, Kumar Mahesh and Alam M S (2021) Image processing techniques to estimate weight and morphological parameters for selected wheat refractions. Scientific Reports. Vol 11. (NAAS Rating: 10.38)

- Sharma Pallavi, Sharma S R, Dhall R K, Mittal T C and Kumar Satish (2021) Variation in quality and acceptability of minimally processed garlic in response to γ-irradiation and packaging during refrigerated storage. Radiat Phys Chem https://doi.org/10.1016/j.radphyschem.2020.109193. (NAAS Rating:7.98)

- Gill Raminder Singh, Singh Sukhmeet, Hans Vishavjeet Singh and Mittal Tarsem Chand (2021). Turmeric (Curcuma longa) drying in natural circulation solar dryer: an experimental evaluation. Journal of Food Process Engineering. https://doi.org/10.1111/jfpe.13765. (NAAS Rating: 7.20)

- Prasad Chavan, Kaur Gagandeep, Alam M S and Kumar Mahesh (2021) Mathematical design and performance investigation of evaporator water cooled storage-cum-mobile thermoelectric refrigerator for preservation of fruits and vegetables. J Food Process Engineering, DOI: 10.1111/jfpe.13770 (NAAS Rating: 8.36)

- Aslam Raouf, Alam M S, Singh Sandhya, Kumar Satish (2021). Aqueous ozone sanitization of whole peeled onion: Process optimization and evaluation of keeping quality during refrigerated storage. LWT- Food Science and Technology 151:1-10 https://doi.org/10.1016/j.lwt.2021.112183 (NAAS Rating:10.10)

- Aslam Raouf, Alam Mohammed Shafiq, Kaur Jaspreet, Panayampadan Afthab Saeed, Dar Owias Iqbal, Kothakota Anjineyulu, and Pandiselvam Ravi (2021). Understanding the effects of ultrasound processing on texture and rheological properties of food. Journal of Texture Studies, DOI: 10.1111/jtxs.12644 (NAAS Rating: 7.90)

- Solanki Chandan, Gupta S K and Alam M S (2021). Microwave-assisted dehulling of pigeon pea (Cajanus Cajan). Agricultural Mechanization in Asia, Africa and Latin America 52(1): 2969-2977. (NAAS Rating: 6.17)

- Kaur Gurjeet, Kaur Preetinder and Mahal AK (2021) Preserving bioactive quality and colour of novel frozen lemongrass puree tablets. Journal of Food Processing and Preservation.6.e16050, https://doi.org/10.1111/jfpp.16050. (NAAS Rating: 8.61)

- Kaur Gurjeet, Kaur Preetinder and Mahal AK (2021) Preserving bioactive quality and colour of novel frozen lemongrass puree tablets. Journal of Food Processing and Preservation.6.e16050, https://doi.org/10.1111/jfpp.16050. (NAAS Rating: 8.61)

- Aslam Raouf, Alam M S, Kaur P (2021) Comparative study on efficacy of sanitizing potential of aqueous ozone and chlorine on keeping quality and shelf-life of minimally processed onion (Allium Cepa L.). Ozone: Science and Engineering DOI: 10.1080/01919512.2021.1904204 (NAAS Rating: 8.60)

- Tak Y, Kaur M, Amarowicz R, Bhatia S and Chirag G. (2021).Pulse derived Bioactive Peptides as Novel Nutraceuticals: A Review. International Journal of Peptide Research and Therapeutics. https://doi.org/10.1007/s10989-021-10234-8 (NAAS Rating: 7.50)

- Kaur M, Tak Y, Bhatia S, Asthir B, Lorenzo JM, Amarowicz R. (2021). Crosstalk during the carbon–Nitrogen Cycle That interlinks the Biosynthesis,Mobilization and Accumulation of Seed Storage Reserves. Int. J. Mol. Sci. (22) 12032. https://doi.org/10.3390/ijms222112032 (NAAS Rating: 10.56)

- Kaur Maninder and Kumar Mahesh (2020) An Innovation in Magnetic Field Assisted Freezing of Perishable Fruits and Vegetables: A review. Food Reviews Int. 36 (8):761-780. DOI:10.1080/87559129.2019.1683746 (NAAS Rating: 12.04)

- Sharma Pallavi, Sharma S R, Dhall R K and Mittal T C (2020) Effect of γ-radiation on post-harvest storage life and quality of onion bulb under ambient condition. J Food Sci Technol 57(7):2534–2544 (NAAS Rating: 7.85)

- Pallavi Sharma, Sharma S R, Dhall R K, Mittal T C and Bhatia Surekha (2020) Physio-chemical behavior of γ -irradiated garlic bulbs under ambient storage conditions J Stored Prod Res https://doi.org/10.1016/j.jspr.2020.101629 (NAAS Rating:7.95)

- Gayas B, Kaur Gagandeep and Singh A (2020) Ultrasound assisted extraction of apricot kernel oil: effect on physicochemical, morphological characteristics, and fatty acid composition. Acta Alimentaria, Vol. 49 (1), pp. 23–31 DOI: 10.1556/066.2020.49.1.4. (NAAS Rating: 6.55)

- Aslam Raouf, Alam M S and Panayampadan Afthab Saeed (2020) Sanitization potential of ozone and its role in postharvest quality management of fruits and vegetables. Food Engineering Reviews. 12(5): 48-67 https://doi.org/10.1007/s 12393-019-09204-0 (NAAS Rating: 10.22)

- Alam MS, Singh A and Chavan P (2020) Influence of shape, pre-treatment and drying air temperature on quality of dried aonla. Agric Eng Int: CIGR Journal 22(1): 145-151. (Impact Factor: 0.41/ NAAS Rating: 6.41)

- Devgan Kirandeep, Kaur Preetinder, Kumar Nitin and Kaur Amrit Mahal (2020) Development and optimization of colour changing indicator labels for assessing headspace gas concentration of yellow bell pepper (Capsicum annuum L). J Food Safety and Food Quality. Vol 71(6): 135-166. (NAAS Rating: 6.38)

- Zalpouri Ruchika, Kaur Preetinder, Kaur Amrit and Kaur Gagandeep (2020) Comparative analysis of optimized physiochemical parameters of dried potato flakes obtained by refractive and convective drying technique. J Food Process Preserv. Vol 45(1) https://DOI: 10.1111/JFPP.15077. (NAAS Rating: 8.61)

- Kaur Preetinder, Zalpouri Ruchika, Singh Manpreet and Verma Sahil (2020) Process optimization for dehydration of shelled peas by osmosis and three?stage convective drying for enhanced quality. Journal of Food Processing and Preservation 44(3) DOI: 10.1111/jfpp.14983 (NAAS Rating: 8.61)

- Kumar N, Kaur P, Devgan K and Attkan A (2020) Shelf life prolongation of cherry tomato using magnesium hydroxide reinforced bio-nanocomposite and conventional plastic films. Journal of Food Processing and Preservation. DOI: 10.1111/jfpp.14379 (NAAS Rating: 8.61)

- Singla M, Kumar A, Kaur P and Goraya RK (2020) Respiratory properties of fresh black carrot (Dacus Carota L.) based upon non-linear enzyme kinetics approach. Journal of Food Science and Technology. DOI: 10.1007/s13197-020-04422-5. (NAAS Rating: 9.12)

- Kaur G and Goswami T K (2020) Physical and sensory characteristics of low sugar dairy dessert (Rasgulla) developed at different level of coconut sap syrup. Journal of Food Science and Technology. 58: 343–348. (NAAS Rating: 9.12)

- Kaur G, Kalia A, and Sodhi H S (2020). Size controlled, time-efficient biosynthesis of silver nanoparticles from Pleurotus florida using ultra-violet, visible range, and microwave radiations. Inorganic and Nano-Metal Chemistry, 50(1): 35-41. (NAAS Rating: 7.51)

- Devi J, Bhatia S and Alam MS (2019) Abiotic elicitors influence antioxidative enzyme activities and shelf life of carrot during storage under refrigerated conditions. J. Plant Growth Regulation. DOI: 10.1007/s00344-019-09954-5. (NAAS Rating: 8.05)

- Aslam R, Alam MS, Saeed AP (2019). Sanitization potential of ozone and its role in postharvest quality management of fruits and vegetables. Food Engineering Reviews https://doi.org/10.1007/s12393-019-09204-0. Pp 1-20. (NAAS Rating: 10.41)

- Kaur Gagandeep, Singh Manpreet and Kaur Preetinder (2019) Effect of operational parameters on physiochemical quality and recovery of spray-dried tomato powder. Journal of Food Processing and Preservation. DOI: 10.1111/jfpp.141201-9. (NAAS Rating: 8.61)

- Kaur G and Goswami T K (2019). Effect of stevia level on chemical, microbiological and sensory properties of dairy dessert at different storage periods and temperatures. Journal of Food Processing and Preservation. 44: e14293. (NAAS Rating: 8.61)

- Sharma S, Kaur Gagandeep and Alam MS (2018). Design, development and evaluation of small scale maize kernel degermer. AMA Agricultural Mechanization in Asia, Africa and Latin America 49(3): 72-78 (NAAS Rating: 6.12)

- Prasad Chavan, Singh A K and Kaur Gagandeep (2018) Recent progress in the Utilization of Industrial Waste and By-products of Citrus Fruits: A Review. Journal of Food Process Engineering DOI: 10.1111/jfpe.12895: 1-10. (NAAS Rating: 7.37)

- Ummat Viruja Singh, A K and Kaur Gagandeep (2018) Effect of aqueous ozone on quality and shelf life of shredded green bell pepper (Capsicum annuum). Journal of Food Processing and Preservationhttps://doi.org/10.1111/jfpp.13718 (NAAS Rating: 6.79)

- Devi J, Bhatia S, Alam M S and Dhillon T S (2018). Effect of calcium and salicylic acid on quality retention in relation to antioxidative enzymes in radish stored under refrigerated conditions. J Food Sci Tech. 55(3):1116–26, https://doi.org/10.1007/s13197-017-3027-4. (NAAS Rating: 7.26)

- Devgan Kirandeep, Kaur Preetinder, Kumar Nitin and Kaur Amrit (2018) Active modified atmosphere packaging of yellow bell pepper for retention of physico-chemical quality attributes. J Food Sci Technol. Vol 56: 878– 888 https://doi.org/10.1007/s13197-018- 3548-5. (NAAS Rating: 9.12)

- Sharma Rudrakshi, Bhatia Surekha and Kaur Preetinder (2018) Influence of packaging and storage conditions on biochemical quality and enzymatic activity in relation to shelf life enhancement of fresh basil leaf. J Food Sci Technol. 55(8):3199–3211 https://doi.org/10.1007/s13197-018-3250-7. (NAAS Rating: 9.12)

- Kaur Gurjeet, Kaur Preetinder and Kaur Amrit (2018) Physico-chemical properties, bioactive compounds and color parameters of coriander puree: effect of pretreatments and freezing. J Food Sci Technol. https://doi.org/10.1007/s13197-018-3272-1. (NAAS Rating: 9.12)

- Bhatia S, Kaur B , Phutela U G and Kumar Parminder (2018) Kinetic and thermodynamic behavior of partially purified cellobiase from Humicola fuscoatra MTCC 1409. Ind. J Biochem Biophs.55: 163-172 (NAAS Rating: 6.39)

- Kaur G, Kalia A and Sodhi H S (2018). Selenium biofortification of Pleurotus species and its effect on yield, phytochemical profiles, and protein chemistry of fruiting bodies. Journal of Food Biochemistry, 42(2), e12467. (NAAS Rating: 9.65)

College of Agricultural Engineering & Technology / Processing & Food Engineering / Academic Programs

The Department is involved in teaching to both undergraduate and post-graduate students. For undergraduate students; it is offering 14 courses including 5courses for the students of College of Agriculture. Sixteen courses are offered to the M-Tech students while 5 courses are designed for Ph-D students of the Department. In addition, 1 seminar for M-Tech and 2 for Ph D students are offered. Since 1969-70, keeping in mind the needs of the state, Department has offered four M-Tech. Degree programmes viz. M-Tech in Processing and Agricultural Structures, Agro Industrial Processing, Sugar Engineering and Processing and Food Engineering (Current). The PG faculty of the Department has been guiding the research programmes of Master and Doctorate students. The department is very popular among the undergraduate students and every year first 11 undergraduate students opt for their project work. There are 12 M-Tech and 4 Ph D seats including 2 seats for ICAR nominees for admission to Masters and 1 for Ph D programmes respectively. One additional seat is reserved for foreigner student in Ph D. So far 180 M-Tech and 39 Ph D scholars have completed their post graduation from the Department. The department has 9 well equipped laboratories and a library. There are 4 pilot plants and a workshop. Majority of faculty is having Ph D qualification and are members of various professional societies like

- Indian Society of Agricultural Engineers

- Association of Food Scientists and Technologists

- Indian Society of Technical Education

- Institution of Engineers etc.

Teaching Assignments (2022-23)

| Course No. | Title of course | Cr. Hrs. |

| Semester I | ||

| Undergraduate Courses | ||

| PFE 304 | Agricultural Structures and Environmental Control | 3(2+1) |

| PFE 305 | Post Harvest Engg. of Cereals, Pulses and Oil Seeds | 3(2+1) |

| PFE 201 | Unit Operations of Food Processing-I | 3(2+1) |

| PFE 301 | Food Process Equipment Design | 3(2+1) |

| PFE 302 | Food Storage Engineering | 3(2+1) |

| ELP 491 | Experiential learning program in Agricultural Engineering | 10(0+10) |

| ME 201 | Heat & Mass Transfer in Food Processing | 3(2+1) |

| PFE 51 | Elementary Agro Processing | 2(1+1) |

| Postgraduate Courses | ||

| PFE-501 | Transport Phenomena in Food Processing | 3(2+1) |

| PFE-502 | Unit Operations in Food Process Engineering | 3(2+1) |

| PFE-503 | Field Crops Process Engineering | 3(2+1) |

| PFE-513 | Agri-Project Planning and Management | 3(2+1) |

| PFE-514 | Farm Structures and Environmental Control | 3(2+1) |

| PFE-591 | Seminar | 1 (0+1) |

| PFE 601 | Textural and Rheological Characteristics of Food Materials | 3(2+1) |

| PFE 604 | Advances in Drying of Food Materials | 3(2+1) |

| Semester II | ||

| Undergraduate Courses | ||

| PFE 204 | Engineering Properties of Agricultural Produce | 2(1+1) |

| PFE 306 | Post Harvest Engineering of Horticultural Crops | 3(2+1) |

| PFE 307 | Dairy and Food Engineering | 3(2+1) |

| PPR 491 | Project Planning and Report Writing | 10 (0+10) |

| PFE 102 | Post Harvest Engineering | 3(2+1) |

| PFE 202 | Unit Operations of Food Processing-II | 3(2+1) |

| PFE 203* | Food Refrigeration and Cold Chain | 3(2+1) |

| PFE 303 | Protected Cultivation and Secondary Agriculture | 2(1+1) |

| ME 106 | Food Thermodynamics | 3(1+2) |

| EE 304 | Instrumentation & Process Control in Food Industry | 3(2+1) |

| Elective Courses | ||

| PFE 403 | Process Equipment Design | 3 (2+1) |

| PFE 404 | Food Plant Design and Management | 3 (2+1) |

| PFE 405 | Food Packaging Technology | 3 (2+1) |

| Postgraduate Courses | ||

| PFE 508 | Fruits and Vegetables Process Engineering | 3 (2+1) |

| PFE-511 | Food Processing Equipment and Plant Design | 2 (1+1) |

| PFE-601 | Advances in Food Process Engineering | 3 (2+1) |

| PFE-604 | Agricultural Waste and By-Products Utilization | 3 (2+1) |

| PFE-692 | Seminar-II | 1 (1+0) |

College of Agricultural Engineering & Technology / Processing & Food Engineering / Facilities & Services

Laboratory facilities:

- Well-furnished undergraduate and postgraduate teaching and research laboratories having equipments Fluidized bed drier, Freeze drier, Spray dryer, Juice extraction, Size reduction, Screen Pre-Cleaner, V-Mixer, Indented cylinder sorter, Hammer mill, Burr mill (vertical & horizontal plate type), Aspirator column, Texture Analyzer, Rheometer, HPLC, GLC, WVTR, Colorimeter, Noise level measurement meter, Digital conductivity meter, Digital moisture meter, Infrared moisture meter, Portable moisture meter, Digital seed counter, Packaging and package testing machinery including vacuum packaging for solids and liquids, shrink wrapping of fresh fruits and vegetables, Vibration tester/table, Compression tester, Drop tester, Burst strength tester

- Pilot Plants for Rice milling, wheat milling, fruit and vegetable processing

- Walk in cold stores for storage of fresh produce

|

|

| Food Engineering Lab | Process Engineering Lab |

|

|

| Quality Control Lab | |

|

|

| Environmental Control and By-product Utilization Lab | Engineering Properties Lab |

|

|

| Post Harvest Technology Lab | Storage Engineering Lab |

|

|

| Packaging Lab | Pilot Plants for Fruit and Vegetable Processing |

|

|

| Pilot Plant for Rice Milling | |

College of Agricultural Engineering & Technology / Processing & Food Engineering / PG Students

List of M.Tech. Students admitted during the year 2020-2021

| Sr. No. | Name of the Student | Admission No. | Major Advisor | Research Topic |

| 1 |

Kritanjal Goswami |

L-2020-AE-241-M |

Dr. Sandhya |

Effect of Cold Plasma Treatment on quality Parameter of Spinach |

|

2 |

Lalremmawii |

L-2020-AE-242-M |

Dr. Satish Kumar |

Enhancement of Juice Recovery from Kinnow (Cirtus reticulate) and Guava (Psidium guajava L.) using Ohmic Heating |

| 3 |

Sukhdeep Kaur |

L-2020-AE-247-M |

Dr. Gagandeep Kaur |

Development of Biodegradable Packaging Material from Groundnut Shell |

List of M.Tech. Students admitted during the year 2021-2022

| Sr. No. | Name of the Student | Admission No. | Major Advisor | Research Topic |

| 1 |

Chitesh Kumar |

L-2021-AE-232-M |

Dr. Manpreet Singh |

Optimization of process parameters for refractance window drying of sliced white button mushrooms (Agaricus bisporus) |

|

2 |

Pritiman Gachhayat |

L-2021-AE-235-M |

Dr. Rohit Sharma |

Development of rapid and non-destructive method for quality estimation in tomato using image processing |

| 3 |

Sukhmanjot Kaur |

L-2021-AE-238-M |

Dr. Sandhya |

Development of sensors based system to determine quality and adulteration in honey |

| 4 |

Vaneet Dhawan |

L-2021-AE-240-M |

Dr. Maninder Kaur |

Augmentation of Juice recovery from tomato (Solanum lycopersicum) and beetroot (Beta vulgaris Rubra) using ohmic heating |

List of M.Tech. Students admitted during the year 2022-2023

| Sr. No. | Name of the Student | Admission No. | Major Advisor | Research Topic |

| 1 |

Anmoldeep Singh |

L-2022-AE-165-M |

Dr. Gurveer Kaur |

|

|

2 |

Mohit Sharma |

L-2022-AE-166-M |

Dr. Satish Kumar |

|

| 3 |

Harwinder Kaur |

L-2022-AE-167-M |

Dr. T.C. Mittal |

|

| 4 |

Simranjeet Kaur |

L-2022-AE-168-M |

Dr. S.R. Sharma |

|

| 5 |

Jaswinder Singh |

L-2022-AE-169-M |

Dr. Mahesh Kumar |

|

| 6 |

Bishal Das |

L-2022-AE-300-M |

Dr. Satish Kumar Gupta |

|

| 7 |

Pratibha Jain |

L-2022-AE-301-M |

Dr. M.S. Alam |

List of Ph.D. Students admitted during the year 2018-19

| Sr. No. | Name of the Student | Admission No. | Major Advisor | Research Topic |

|

1 |

Thutturu Sravan |

L-2018-AE-125-D |

Dr. S.R. Sharma |

Development and evaluation of spray chilling encapsulation system for black carrot juice |

List of Ph.D. Students admitted during the year 2019-20

| Sr. No. | Name of the Student | Admission No. | Major Advisor | Research Topic |

|

1 |

Raouf Aslam |

L-2019-AE-08-D |

Dr. M.S. Alam |

Aonla Juice Processing using Ohmic Heating assisted Vacuum Evaporation |

| 2 |

Baldev Singh Kalsi |

L-2019-AE-160-D |

Dr. Sandhya |

Development of process protocol for the production of powder from stevia (stevia rebaudiana ) |

|

3 |

Kulwinder Kaur |

L-2019-AE-161-D |

Dr. Satish Kumar |

Development of Protocol for Postharvest Quality Management of Stored Mung Bean using Microwave and Ozone |

| 4 |

Potdar Pratik Pandit |

L-2019-AE-162-D |

Dr. Preetinder Kaur |

Development of Paddy Straw Based Bio-composite Packaging Material for Fresh Products |

| 5 |

Ruchika Zalpouri |

L-2019-AE-163-D |

Dr. Manpreet Singh |

Development and evaluation of solar assisted refractance window dryer for vegetable purees |

List of Ph.D. Students admitted during the year 2019-20

NIL

List of Ph.D. Students admitted during the year 2021-22

| Sr. No. | Name of the Student | Admission No. | Major Advisor | Research Topic |

|

1 |

Kirti Kumari |

L-2021-AE-163-D |

Dr. Mahesh Kumar |

- |

List of Ph.D. Students admitted during the year 2022-23

| Sr. No. | Name of the Student | Admission No. | Major Advisor | Research Topic |

|

1 |

Kanika Aggarwal |

L-2022-AE-85-D |

Dr. S.R. Sharma |

|

|

2 |

Jay Kumar Thakur |

L-2022-AE-86-D |

Dr. T.C. Mittal |

- |