62nd Year of Education & Service

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Faculty

Name : |

Dr Ashwani Kumar Soni |

Designation : |

Senior Scientist |

Office Phone : |

0161-2401960 ext 278 |

Mobile : |

09417789138 |

Email (Office) : |

ashwanisoni@pau.edu |

Research Areas : |

-- |

Researcher ID's : |

-- |

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Home

The Department of Renewable Energy Engineering (earlier known as School of Renewable Energy Engineering/School of Energy Studies for Agriculture) was established in 1984 for effective planning and implementation of its programme of advanced training, research & development in the field of Renewable Energy. A number of research projects funded by various State, National and International organizations such as: PSEB, PEDA, PSCST, ICAR, MNRE, TERI, DST, FAO/UNDP, UGC, BARC etc. have been successfully completed. The mandate of the Department is to develop and disseminate integrated renewable technologies viz., solar, biogas and biofuel technologies. The current areas of research are : utilization of agricultural residues including paddy straw as source of energy through bioconversion and thermal conversion route, solar thermal energy for industrial and agricultural applications, slurry handling and value addition of bio-digested slurry, lignin-silica solubilization of paddy straw for increasing biogas production, biofuels generation and nutraceutical production from micro-algae. The Department has also initiated work on energy management in agriculture and agro-industries. The Department offers Ph.D. programme in Renewable Energy Engineering from year 2023-24 and earlier offered Ph.D. programme in Energy Science and Technology.

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Head of Department

Name : Dr. Rajan Aggarwal

Address : Principal Scientist-cum-Head, Department of Renewable Energy Engineering

Office : 91-0161-2401960-79 Ext. 278, Ext-322

Phone : 9872208744

E-Mail : rajanaggarwal1@pau.edu

Brief Introduction

Dr. Rajan Aggarwal working as Principal Scientist, Department of Soil and Water Engineering, Punjab Agricultural University, Ludhiana. He was bestowed Prof. Manjeet S. Chinnan Distinguished Professor Chair Award and also awarded Gold Medal-2017 by Soil Conservation Society of India. Previously he remains head of the department of Soil and Water Engineering (2015-19). He is also Chief Scientist of AICRP on “Irrigation Water Management” and Principal Investigator of projects entitled “Punjab: Pilot Implementation of Direct Benefit Transfer for Electricity (DBTE) to Agriculture” and “Use of Big Data Analytics for Adapting Impact of Climate Change on Water Resources”. He has already completed eleven research projects as PI/Co-PI/Collaborator on Groundwater Resource Management to Mitigate the Impact of Climate Change in Punjab and Haryana, Promotion of Micro irrigation, District Irrigation Plans, Decision support system for enhancing water productivity, Soil and water management in high intensive cropping regions, Farmers Participatory Research Programme etc. The research on groundwater modeling, rainwater harvesting, climate change, pump testing and drip irrigation has proved to be beneficial for water resource management of the State. He has designed and installed more than 200 recharge structures for rainwater harvesting, agricultural runoff and surplus canal water at different sites in the state. He has more than 230 publications in international/national journals, popular articles, book chapters etc. authored a book entitle “Fundamentals of Groundwater and Drainage Engineering”. Dr. Aggarwal is associated with National Board of Accreditation as Expert Member, Department of Science and technology as Expert Member of the committee on “Sustainable agriculture and Rural Transformation Holistic Initiative (SARTHI), State level Ground water Coordination (SGWCC) for coordination and implementation of National Project on Aquifer Management (NAQUIM), and District Irrigation Plan under PMSKY. He has guided several M.Tech and Ph.D students for their research. He has done extensive extension work in KVK Bahowal for Soil and water conservation.

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Thrust Areas

- Utilization of agricultural residues including paddy straw, cattle dung and poultry droppings as source of energy through bioconversion and thermal conversion routes

- Slurry handling and value addition of bio-digested slurry by industrial enzymes production

- Lignin-silica solubilization of paddy straw for increasing biogas production

- Bio-fuels generation and nutraceutical production from micro-algae

- Bioenzymes preparation from fruit and vegetable wastes and its characterization

- Solar thermal energy for industrial and agricultural application

- Energy auditing and management in agriculture and agro-industries

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Faculty

Faculty

| S.No | Name & Designation | E-Mail/Telephone |

| 1. | Dr Ashwani Kumar Soni Senior Scientist |

ashwanisoni@pau.edu 09417789138 |

| 2. | Dr Iqbal Singh Scientist (REE) |

erisingh@pau.edu 9878888295; 9463186295 |

| 3. | Dr Manpreet Singh Scientist (REE) |

manpreet-sesa@pau.edu 09814628993 |

| 4. | Dr Monica Sachdeva Taggar Biochemist |

monicasachdeva@pau.edu 9814685300 |

| 5. | Dr Ritu Dogra Professor(REE) |

ritudogra@pau.edu 9780013356 |

| 6. | Dr Sarbjit Singh Sooch Principal Scientist (REE) |

sssooch@pau.edu 9501034513 |

| 7. | Dr Shashi Kumar Singh Principal Scientist( REE) |

sksingh@pau.edu 9888997292 |

| 8. | Dr Sukhmeet Singh Principal Scientist (REE) |

sukhmeet70@pau.edu 9465195252 |

| 9. | Dr Urmila Gupta Phutela Principal Scientist (REE) |

urmilphutela@pau.edu 9878717711 |

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Faculty Distinctions

| Name of the Faculty member | Year | Nature of work |

| Dr. Manpreet Singh | 2012 | 1st Prize for Poster presentation entitled “Optimization of process parameters for modified atmosphere packaging of minimally processed fresh baby corn” at National Seminar on Sustainable Agriculture and Food Security: Challenges in Changing Climate (SAFS-2012) held at HAU, Hisar during March 27-28, 2012. |

| Dr. Urmila Gupta Phutela | 2012 | 1st prize in poster presentation for research article in International Conference on Sustainable Agriculture for Food and Livelihood Security held at PAU in November 2012 |

| Dr. Varinder Singh Saimbhi | 2012 | 1st prize in poster presentation for research article in International Conference on Sustainable Agriculture for Food and Livelihood Security held at PAU in November 2012 |

| Dr. Manpreet Singh | 2012 | 2nd Prize for Poster presentation entitled “Modeling gas exchange dynamics of fresh-cut vegetables under modified atmospheres” under the Theme Area D at International Conference on Sustainable Agriculture for Food and Livelihood Security held at PAU, Ludhiana during November 27-29, 2012. |

| Dr Ashwani Kumar Soni and Dr. Sarbjit Singh Sooch | 2015 | Award for Best Poster for paper titled “Computer Aided Design of Modified PAU Janta biogas plant for Punjab Region” in 49th Annual Convention of Indian Society of Agricultural Engineers (ISAE) and Symposium on Engineering Solutions for Sustainable Agriculture and Food Processing held on February, 23-25, 2015 at PAU Ludhiana |

| Dr. Manpreet Singh | 2015 | Outstanding Poster Appreciation Award for poster entitled “Green packaging for foods: An environment friendly perspective” by Kaur P, Bhatia S and Singh M at Regional Seminar on Geospatial Technology in Natural Resource Management organized by ISRS at PRSC, Ludhiana held during March 17-18, 2015. |

| Dr. Urmila Gupta Phutela | 2015 | Second prize for best poster presentation entitled “ Application of microbes in Food Biotechnology “ in the National Symposium on Modern Agro- Technologies for Nutritional Security and Health national symposium held at Dr. Y. S. Parmar university of Horticulture and forestry, Nauni, Solan (H.P on 21-23 April 2015 |

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Important Achievements

1. PAU fixed dome type Family size Biogas Plant having capacity from 1m3/day to 25m3/day

PAU, Ludhiana designed and developed this biogas plant during the year 2005 to cater to the needs of individual’s families. This, essentially, is a mixture of Janta and Deenbandhu design of biogas plants. The gas-holder is hemispherical in shape and is structurally safe & crack-resistant. The construction of this type of plant is easy and is not very difficult from the method for the Deenbandhu Biogas Plant. This plant can be constructed with around 60 – 70% cost as compared to the cost of other conventional floating drum type (KVIC) biogas plant. These plants have been constructing by skilled workers / masons trained by PAU, Ludhiana.The ICAR has approved this design and has recommended for the" Transfer of Technology to the farmers/ end-users. The MNRE has accepted this design for the extensive adoption by end-users for the production of biogas and cogeneration. Till date, 10,000 such biogas plants have been installed in Punjab State. This technology has been commercialized by PAU, Ludhiana on 10.03.2021 and Memorandum of Agreement has been signed with 06 firms.

2. Modified PAU fixed dome Janta model Biogas Plant having capacity from 25m3/day to 500m3/day

PAU, Ludhiana designed and developed this biogas plant during the year 2005 to cater to the needs of dairy farms, poultry farms, pig farms, industries, institutes like gaushalas, educational institutions, religious institutions, NGO’s, societies etc. This, essentially, is a mixture of Janta and Deenbandhu design of biogas plants. The gas-holder is hemispherical in shape and is structurally safe & crack-resistant. The construction of this type of plant is easy and is not very difficult from the method for the Deenbandhu Biogas Plant. This plant can be constructed with around 60 – 70% cost as compared to the cost of other conventional floating drum type (KVIC) biogas plant. These plants have been constructing by skilled workers / masons trained by PAU, Ludhiana. The ICAR has approved this design and has recommended for the" Transfer of Technology to the farmers/ end-users. The MNRE has accepted this design for the extensive adoption by end-users for the production of biogas and cogeneration. Till date, 130 such biogas plants have been installed in Punjab State and 35 biogas plants have been installed in other 13 States of India. This technology has been commercialized by PAU, Ludhiana on 01.02.2023 and Memorandum of Agreement has been signed with 17 firms.

3. Paddy Straw based Biogas Plant made up of Mild Steel (M.S.) Sheet (above the ground)

PAU has designed biogas plant made up of M.S. sheet (digester above the ground and floating drum gas holder) during the year 2017 for anaerobic digestion of paddy straw for biogas production. The life of this structure is around 15 years and the advantage of this structure is that the whole structure will be above the ground due to which the vacating of the plant is very easy. This process of Dry Fermentation is a batch process, once the digester is loaded and activated, would produce sufficient gas for a period of 3 months. The digested material so produced from such anaerobic digestion is good quality manure ready for use in the fields. Till date, 20 such biogas plants have been installed in Punjab State. This technology has been commercialized by PAU, Ludhiana on 19.01.2021 and on 19.01.2021 and Memorandum of Agreement has been signed with 10 firms.

4. PADDY STRAW BALE GEYSER

Paddy straw bale combustor/geyser for heating water has been developed. A paddy straw bale is combusted inside it for heating water in annular space. About 100 litres of water can be heated to 45-500C in 3-4 hours. The water once filled in the geyser remains hot for up to 24 hours or even more. The most convenient use of the paddy straw bale geyser would be starting the geyser at night and hot water can be used in the morning time. The fuel, i.e. paddy straw bales, is not big problem for a moderate level farmer in the state. A farmer can easily stock enough paddy straw bales (about 100), in small shed, for full winter season without much of cost and efforts. A provisional patent has already been filed (Indian Patent Application No. 2038/DEL/2015) in Indian patent office. The paddy straw bale combustor/geyser has been approved by PAU research evaluation committee in its 248th meeting held on 14-12-2015 for commercialization.

|

|

|

| Farmer using paddy straw bale geyser at his farms | Rectangular section paddy straw bale geyser. | |

5. Forced Circulation Solar Dryer

The ‘Forced Circulation Solar Dryer’ is a large capacity solar dryer suitable for commercial drying and has been developed by Department of Renewable Energy Engineering, Punjab Agricultural University, Ludhiana under All India Coordinated Research Project on Energy in Agriculture and Agro-based Industries funded by Indian Council of Agricultural Research (ICAR). It can be designed for any capacity requirement above 100 kg. It can be used for drying vegetables, spices, fruits etc. in the form of small solid pieces. A few examples are, turmeric (curcuma longa), fenugreek leaves (trigonellafoenum-graecum), amla (phyllanthusemblica), harad (terminalia chebula) chilly (capsicum frutescens), jamun (syzygiumcumini), bittergourd (momordicacharantia), ginger (zingiber officinale), lantil doughnut (wadian) etc. The dryer overcomes the limitation associated with traditional drying method i.e. open sun drying (OSD). The dryer requires electric energy for its operation, which can be met from main grid or solar photovoltaic modules. It has been approved by the University Research Evaluation Committee. For manufacturing and marketing of this technology, the Punjab Agricultural University, Ludhiana has signed a MoA with M/s Vishivkarma Solar Energy Corporation, Phillaur, Distt. Jalandhar.

6. Solar Dryer with Re-circulation

It can be used to dry various products (vegetables, spices etc.) under hygienic conditions for commercial purpose. It has solar air heater, drying chamber, air blower and air dampers operated with humidity controller. It works in controlled re-circulation air loop to use maximum heating capacity of unspent air leaving the dryer. The relative humidity of air in re-circulation air loop is kept below the set value by automatically mixing of ambient air into recirculation air loop by opening and closing of air dampers. When dampers open, some amount of recirculation air is thrown out of the loop and same amount of ambient air mixes with recirculation drying air, thereby reducing its RH and temperature. It has been approved by the University Research Evaluation Committee. For manufacturing and marketing of this technology, the Punjab Agricultural University, Ludhiana has signed a MoA with M/s Vishivkarma Solar Energy Corporation, Phillaur, Distt. Jalandhar.

7. SPV operated evacuated tube solar dryer

It has separate solar collector and dehydration chamber. The solar collector has evacuated tube collector for air heating. The evacuated tubes used in this dryer have both ends open for through flow of air. The dehydration chamber is fixed above the solar collector. At top of dehydration chamber, an electric exhaust fan is provided so as to force air through dehydration chamber and solar collector. The electric fan takes DC electricity input from solar PV module. The air in evacuated tubes gets heated because of collection of solar radiation by evacuated tubes and moves upwards due to suction by electric fan and flows through drying product placed on trays in dehydration chamber. The air after picking moisture from the drying product leaves from the top of dehydration chamber and an equal amount of the ambient air enters from lower end of evacuated tubes. This process continues as long as solar radiation falls on the solar collector. Solar PV powered fan has advantage that the electric fan runs only for the period for which solar radiation is available for heating of air. It has been approved by the University Research Evaluation Committee. For manufacturing and marketing of this technology, the Punjab Agricultural University, Ludhiana has signed a MoA with M/s Raftaar Professional Engineering Company, Ludhiana, and M/s Vishivkarma Solar Energy Corporation, Phillaur, Distt. Jalandhar.

8. Evacuated tube collector solar dryer employing conventional evacuated tubes

It has separate solar collector and dehydration chamber. The solar collector has evacuated tube collector for air heating. The conventional evacuated tubes are used in this dryer. At bottom of dehydration chamber, an electric exhaust fan is provided so as to force air through dehydration chamber and solar collector. The electric fan takes DC electricity input from solar PV module. The air in evacuated tubes gets heated because of collection of solar radiation by evacuated tubes and moves upwards due to suction by electric fan and flows through drying product placed on trays in dehydration chamber. The air after picking moisture from the drying product leaves from the top of dehydration chamber and an equal amount of the ambient air enters from both sides of the tubes header. It has been approved by the University Research Evaluation Committee. For manufacturing and marketing of this technology, the Punjab Agricultural University, Ludhiana has signed a MoA with M/s Vishivkarma Solar Energy Corporation, Phillaur, Distt. Jalandhar.

9. PAU SOLAR ENERGY GADGETS FOR SALE UNDER REVOLVING FUND SCHEME

Advanced Domestic Solar Dryer

Loading capacity = 1-3 kg

- Products that can be dried: turmeric, chilly, methi, palak, ginger, garlic, wadian, vegetables for pickle etc.

- Drying time: 2 - 4 days

- Only solar energy required for drying

- Drying under shade

- Dryer can be easily moved inside when not in use

- No attention required during bad weather/off sunshine hours

- In comparison to open sun dried products, solar dried products are clean, have better quality and take less drying time

- Cost = presently not available.

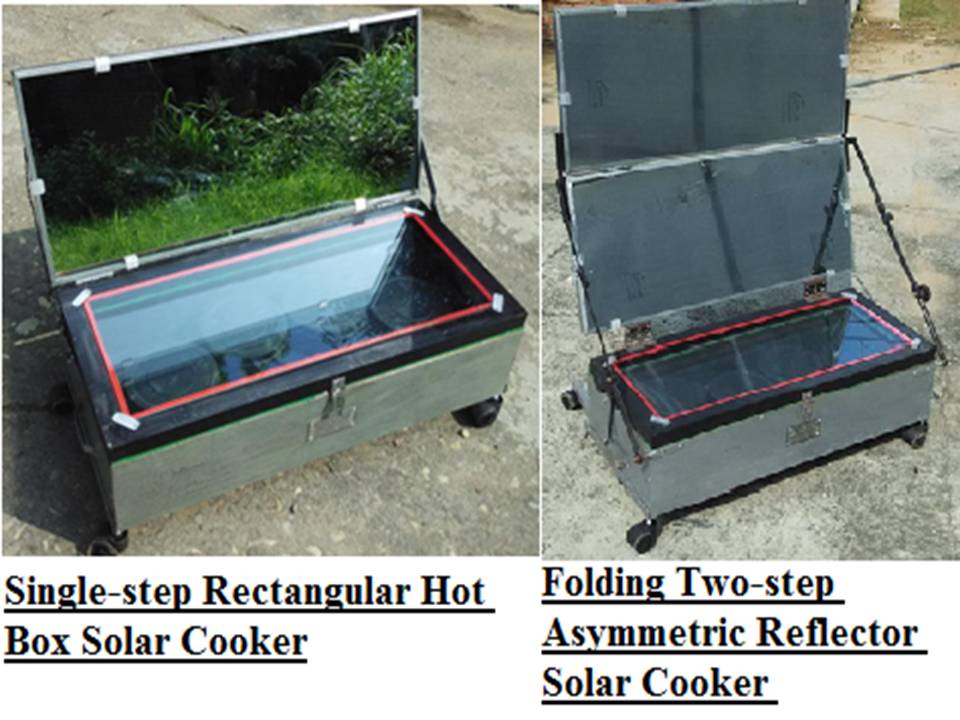

Solar Cooker

Two models:

- Single-step Rectangular Hot Box Solar Cooker

- Folding Two-step Asymmetric Reflector Solar Cooker

- Three cooking vessels

- Needs less tracking as compared to conventional square hot box solar cooker available in market

- Cooking accomplished by boiling

- Food that can be cooked: dal, rajma, chana, meat, rice, cake, etc.

- Frying and chapati making cannot be done

- Cooking time varies with product (generally 1-3 hours)

- Cooking time less for two step solar cooker as compared to single step solar cooker

10. Binderless Briquettes from Chopped Paddy Straw

Paddy straw can be utilized for production of Binderless Briquettes from Chopped Paddy Strawwhich can be used in various thermal applications for cooking, boiling, heating low temperature furnaces and steam generation in boilers as a substitute of wood preferably in co-firing mode. This will provide energy security, self-reliance in energy, help in creating rural employment and generation of rural income.

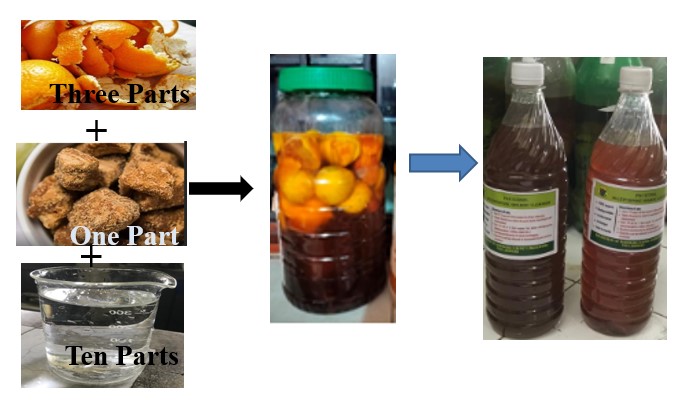

11. Bioenzymes From Kinnow Waste: An Organic Cleanser

The kinnow peels, droppings as well as waste from the processing industries can be utilized for the production of bioenzymes. The bioenzymes are fermented organic formulation and also known as an eco-enzyme (natural and eco-friendly), garbage enzyme, kitchen enzyme or fruit enzyme. It can be used as an effective alternative to harsh chemicals such as harpic, phenyl and chemical solutions that are used in households to clean bathrooms, toilets, floors, tiles and other surfaces. The prepared bioenzyme is transparent, light brown in colour with sweet sour odour and its pH ranges between 3.0 to 4.0. No pathogens have been detected in the bioenzymes and heavy metals are either absent or below permissible limits which indicates that it is safe to use for various applications. The shelf-stability of bioenzymes are approximately one year without any contamination. Technology for Preparation of Bioenzyme from Kinnow Waste: A fermented Organic Cleanser has been recommended by 297th REC meeting held on 25.7.23

List of Patents obtained or applied for during last five years

Granted:

| S. No. | Title of Patent | Patent No. | Date Of Year |

|

1. |

An improved solar dryer using packed bed natural circulation |

292043 |

23.01.2018 |

|

2. |

All-glass Evacuated Tube Solar Water Heater |

323425 |

22.10.2019 |

|

3. |

A fungal consortium for degradation of lignin and or silica, process therefor and application thereof |

429474 |

20.04.2023 |

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Current Projects

All India Coordinated Research Project on Energy in Agriculture and Agro-based industries (AICRP on EAAI)

Component: Solar Energy Component (DRET-SET)

| Sr. No | Name of Sub-project | Date of start | Date of completion |

|

1. |

Development of solar dryer with heat storage |

April, 2020 |

March, 2023 |

|

2. |

Development of a solar drying system for marigold flowers to extract seeds |

April, 2021 |

March, 2023 |

|

3. |

Design Improvements in Forced Circulation Solar Dryer |

April, 2023 |

March, 2025 |

|

4. |

Design modification of evacuated tube solar air heater and its performance evaluation |

April, 2023 |

March, 2025 |

Component: Bio Conversion Technology Component (DRET-BCT)

| Sr. No | Name of Sub-project | Date of start | Date of completion |

|

1. |

Development of fast decomposition methodology for biogas generation from paddy straw |

April, 2021 |

March, 2023 |

|

2. |

Development and evaluation of Prototype for value addition of Paddy straw ash by silica extraction |

April, 2021 |

March, 2023 |

|

3. |

Valorisation of paddy straw into industrially valuable products |

April, 2022 |

March, 2024 |

|

4. |

Design and development of semi continuous type biogas plant for Paddy straw |

April, 2023 |

March, 2025 |

|

5. |

Bio methanation potential of Sweet Sorghum grown in waste water of sewage treatment plant at PAU |

April, 2023 |

March, 2025 |

Component: Demonstration of Renewable Energy System (DRES)

| Sr. No | Name of Sub-project | Date of start | Date of completion |

|

1. |

Installation, Demonstration and Performance Evaluation of different biogas technologies in different States of India |

April, 2021 |

March, 2023 |

|

2. |

Enhancing biogas production by supplementation of slurry in paddy straw-based biogas plant |

April, 2021 |

March, 2023 |

|

3. |

Dissemination of paddy straw bale geyser technology for utilization in different sectors of society |

September, 2022 |

March, 2024 |

|

4. |

Technical support for Installation of 20 Modified PAU fixed dome type Janta Model Biogas plants having capacity from 100 to 500 m3/day for decentralized power generation in Punjab State (One in each District) under GOBAR-DHAN (Galvanizing Organic Bio-Agro Resources Dhan) Scheme |

April, 2022 |

March, 2025 |

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Important Publications

| Sr. No. | Publications | NAAS rating |

|

1. |

Bhambota S, Dixit A K, Manes G S, Dhatt A S, Singh S K and Singh A (2018) Field evaluation of a semi-automatic vegetable transplanter for major vegetable crops. Indian Journal of Agricultural Sciences 88(11):1755-59. |

6.22 |

|

2. |

Dar R A , Dar E A, Kaur A and Phutela U G (2018) Sweet sorghum-a promising alternative feedstock for biofuel production. Renew Sustainable Energy Reviews82 (2018) 4070–4090 |

15.18 |

|

3. |

Dar R A and Phutela U G (2019) Enzymatic and Hydrothermal Pretreatment of Newly Isolated Spirulina subsalsa BGLR6 Biomass for Enhanced Biogas Production. Waste and Biomass Valorization (https://doi.org/10.1007/s12649-019-00712-y) |

7.87 |

|

4. |

Garg D , Dar R A and Phutela UG (2022) Characterization of novel euryhaline microalgal cultures from Punjab, India for bioactive compounds. Archives of Microbiology204:370-83 |

7.88 |

|

5. |

Gill N, Dogra R and Dogra B (2018). Influence of moisture content, particle size and binder ratio on quality economics of rice straw briquettes. Bioenergy Research11(1): 54-68. |

9.31 |

|

6. |

Kaur A, Taggar M S, Kalia A and Singh M(2022) Nitrate-induced carbohydrate accumulation in Chlorella sorokiniana and its potential for ethanol production. Bioenergy Research 15:253-263. |

8.81 |

|

7. |

Kaur J, Taggar M S, Kalia A, Sanghera G S, Kocher G S and Javed M (2022) Valorization of sugarcane bagasse into fermentable sugars by efficient fungal cellulolytic enzyme complex. https://doi.org/10.1007/s12649-022-01918-3 |

9.70 |

|

8. |

Kaur P, Taggar M S and Kalia A (2021) Characterization of magnetic nanoparticle–immobilized cellulases for enzymatic saccharification of rice straw. Biomass Conv Bioref11: 955–969. |

8.60 |

|

9. |

KaurA, Taggar M S, Kalia A and Singh M (2022) Nitrate?induced carbohydrate accumulation in chlorella sorokiniana and its potential for ethanol production. BioEnergy Research. 15(1) 253-263. doi: 10.1007/s12155-021-10292-2. |

8.81 |

|

10. |

Kaur D, Singh M, Zalpouri R and Singh I (2022) Osmotic dehydration of fruits using unconventional natural sweeteners and non-thermal-assisted technologies: A review Journal of Food Processing and Preservation. 2022;00:e16890. |

8.61 |

|

11. |

Kaur K, Kaur P, Kumar S, Zalpouri R and Singh M (2022) Ozonation as a Potential Approach for Pesticide and Microbial Detoxification of Food Grains with a Focus on Nutritional and Functional Quality. Food Reviews International, DOI: 10.1080/87559129.2022.2092129. |

12.04 |

|

12. |

Kaur P, Zalpouri R, Singh M and Verma S (2020) Process optimization for dehydration of shelled peas by osmosis and three-stage convective drying for enhanced quality. J Food Process Preserv. 2020;00:e14983. |

7.29 |

|

13. |

Kaur S, Singh M, Zalpouri R, Kaur K (2023) Potential application of domestic solar dryers for coriander leaves: Drying kinetics, thermal efficiency, and quality assessment. Environmental Progress and Sustainable Energy doi:10.1002/ep.14092 |

8.82 |

|

14. |

Kumar M, Dogra R, Narang M K, Singh M and Mehan S (2021) Development and evaluation of direct paddy seeder in a puddled field. Sustainability 13 (5): 2745. https://doi.org/10.3390/su13052745 |

8.59 |

|

15. |

Sharma N, Gupta U and Singh I (2023) Co-digestion of euryhaline microalgae Scenedesmus sp. MKB. with paddy straw for biogas production. Environ Eng Res28 (2): 210298-210306 |

7.44 |

|

16. |

Parmar R P, Singh S K and Singh M (2021) Bioefficacy study of agricultural spraying system for Unmanned Aerial Vehicle to manage pests in cotton, rice and moong. Indian Journal of Agricultural Sciences 91 (9): 1373–7. |

6.21 |

|

17. |

Sidhu G K, Singh M and Kaur P(2019) Effect of operational parameters on physicochemical quality and recovery of spray?dried tomato powder. J Food Process Preserv. 2019;00:e14120. https ://doi.org/10.1111/jfpp.14120. |

7.51 |

| 18. |

Singh A K, Manes G S, Dixit A, Singh S K and Singh M (2019) Development and evaluation of multi nozzle backpack type power sprayer. Indian J Agril Sci 89(6): 1005-10. |

6.23 |

| 19. |

Singh M, Sidhu H S, Singh Y, Singh S K and Pandey H S (2020) Performance evaluation of automatic vis-à-vis manual topographic survey for precision land levelling. PrecisionAgric 21,300–310 (2020).https://doi.org/10.1007/s11119-019-09669-3 |

9.36 |

| 20. |

Singh S, Gill R S, Hans V S and Mittal TC (2022). Experimental performance and economic viability of evacuated tube solar collector assisted greenhouse dryer for sustainable development. Energy 241 (2022) 122794. |

13.14 |

| 21. |

Singh S, Gill R S, Hans V S and Singh M (2021). A novel active-mode indirect solar dryer for agricultural products: Experimental evaluation and economic feasibility.Energy,222,119956.https://doi.org/10.1016/j.energy.2021.119956. |

12.08 |

| 22. |

Singh S, Gill RS, Hans VS andSingh, M. (2021) A novel active-mode indirect solar dryer for agricultural products: Experimental evaluation and economic feasibility.Energy222: 119956. |

12.08 |

| 23. |

Singla M, Hans VS and Singh S (2022). CFD analysis of rib roughened solar evacuated tube collector for air heating. Renewable Energy 183: 78-89. https: //doi.org /10.1016/j.renene.2021.10.055. |

14.00 |

| 24. |

Singla M, Singh M and Dogra R. (2020). Experimental investigation of imbert downdraft gasifier using rice straw briquettes. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, DOI: 10.1080/15567036.2020.1771478. |

6.89 |

| 25. |

Verma N, Taggar M S, Kalia A and Javed M (2022) Comparison of various delignification/desilication pre-treatments and indigenous fungal cellulase for improved hydrolysis of paddy straw. Biotech312 (7):1-14 https://doi.org/10.1007/s13205-022-03211-5. |

8.41 |

| 26. |

Zalpouri R, Singh M, Kaur P and Singh S (2022) Refractance Window Drying-a Revisit on Energy Consumption and Quality of Dried Bio?origin Products. Food Engineering Reviews. 14(2): 257-70.https://doi.org/10.1007/s12393-022-09313-3. |

12.74 |

| 27. |

Zalpouri R, Singh M, Kaur P, Kaur A, Gaikwad K K and Singh A (2023) Drying kinetics, physicochemical and thermal analysis of onion puree dried using a refractance window dryer. Processes- MDPI. DOI: 10.3390/pr11030700 |

9.35 |

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Academic Programs

Ph.D Program: The Department offered Ph.D. degree in Energy Science and Technology till session 2022-23 and will offer Ph.D. degree in Renewable Energy Engineering from session 2023-24 the following sub-areas:

- Solar thermal energy for industrial and agricultural applications.

- Solar energy utilization in farm implements.

- Energy auditing of farm machinery implements and processes and agro-industries.

- Bio-gas generation from agricultural bio-mass by bio-conversion route.

- Slurry handling and value addition of bio-digested slurry from bio-gas plants.

- Bio-fuels generation from agricultural bio-mass including micro-algae.

- Thermo-chemical conversion of biomass

- Thermo-chemical conversion of bio-mass.

Post graduate Courses

| Core Courses (Requirement: 12 Credits) | |||

|

Course No. |

Course Title |

Credit Hours |

Suggested Semester |

|

REE-601* |

Biochemical Conversion of Biomass |

2+1 |

I |

|

REE-602* |

Thermo-Chemical Conversion of Biomass |

2+1 |

II |

|

REE-603* |

Advances in Renewable Energy Systems |

2+1 |

I |

|

REE-604 |

New Alternate Energy Systems |

2+1 |

II |

|

REE-605* |

Fuels and Combustion |

2+1 |

I |

|

REE-606 |

Advances in Biogas Technology |

2+1 |

II |

|

REE-607 |

Solid Waste and Waste Water Management |

2+1 |

I |

|

REE-608 |

Advanced Photovoltaic Power Generation |

1+1 |

II |

|

REE-609 |

Energy Planning, Management and Economics |

3+0 |

I |

|

REE-610 |

Renewable Energy for Industrial Application |

2+1 |

II |

|

REE-611 |

Biofuel Technologies and Applications |

1+1 |

I |

|

REE-612 |

Energy Modelling and Simulation |

1+1 |

II |

|

Total |

22+11 |

||

Minor Courses (Requirement: 06 Credits)

| Course No. | Course Title | Credit Hours | Suggested change | Suggested Semester | Remarks |

Minor courses may be selected from subjects closely related to student’s major subject. A student can opt any course related to his/her research work of 500 series and above from the following fields of specialization Farm Machinery and Power Engineering , Mechanical Engineering, Processing and Food Engineering, Soil and Water Conservation Engineering , Irrigation and Drainage Engineering

Supporting Courses (Requirement: 05 Credits)

| Course No. | Course Title | Credit Hours | Suggested change | Suggested Semester | Remarks |

Courses to be added from subject matter fields (other than Minor) related to area of special interest and research problem of student.

List of other Essential Requirements

| Course Code | Course Title | Credit Hours | Suggested Semester | Remarks |

| REE-691 | I | 1+0 | I/ II | - |

| REE-692 | Seminar II | 1+0 | I/ II | - |

| REE-699 | Doctoral Research | 0+75 | I/ II | - |

College of Agricultural Engineering & Technology / Renewable Energy Engineering / Facilities & Services

|

Renewable Energy Demonstration Area |

|

|

Biogas Laboratory |

|

|

Pathak Energy Workshop Workshop is used for fabrication of items, used in gasifier. It also houses a Biodiesel laboratory and Biomass analysis laboratory. |

|

|

Biomass Analysis Laboratory The Biomass Analysis Laboratory houses the equipments for analysis of bio-chemical and thermo-chemical properties of different solid/liquid/gaseous samples especially agricultural crop residues etc. A Bomb Calorimeter of MAC make is used for analysis of gross heating values of various samples. The laboratory also has an Elemental Analyzer (EuroVector EA-3000) for analyzing carbon, hydrogen, nitrogen, sulphur and oxygen present in different biological samples. To analyze (identify and quantify) volatiles, toxicants, indoor air, petroleum hydrocarbons, organo-metallic compounds and natural or agricultural products, the laboratory has two Gas Chromatograph machines (Nucon GC-5765 and PerkinElmer Clarus 500). The laboratory also has Flame photometer (Elico CL-361) for inorganic chemical analysis for determining the concentration of certain metal ions such as sodium, potassium, lithium, calcium, Cesium, etc. The laboratory is also equipped with Flash Point Apparatus (Tanaka APM-7) for measuring flash points of different substances according to standard test methods. |

|

|

Biodiesel laboratory A biodiesel laboratory has been set up with various instruments like Orbital shaking incubator, Soxhlet extraction unit, Laminar flow chamber, Ultrafiltration assembly, UV-visible spectrophotometer for biochemical analysis and laboratory scale production of biofuels. |

|

|

Liquid Fuel Testing Laboratory The Liquid Fuel Testing Laboratory has Computerized Variable Compression Ratio Multi-Fuel Engine Test Rig to find the performance and combustion parameters of various fuels like diesel, petrol, auto-gas (LPG/CNG/LNG), bio-diesel, bio-ethanol or its blended fuels. The compression ratio of the engine is variable from 5:1 to 20:1. A unique provision is been made to vary the spark timing of the engine. Wide range of combustion studies can be conducted with the help of this setup. Engine Combustion and performance parameters like Actual volume of Air, Volumetric Efficiency, Specific fuel consumption (SFC), Brake Thermal Efficiency, Brake power, Heat Balance chart, mechanical efficiency, Frictional Power , indicated Power, PV and P-θ diagrams, Mass Fraction Burnt Angle, Estimated End of Combustion Angle (EEOC), Gross IMEP, Maximum Heat Release Rate, Maximum Heat Release rate crank angle, Maximum pressure rise rate, Maximum pressure rise rate crank angle, Maximum pressure, Maximum pressure crank angle, Start of Combustion, Total heat release, Ignition delay, ignition duration can be studied. |

|

|

Solar Energy The solar energy laboratory is an important component of the school. The laboratory houses a facility for manufacturing and testing of solar thermal energy gadgets for research work under AICRP on Renewable Sources of Energy for Agricultural and Agro-based Industries. Instruments such as pyranometers, temperature indicators, temperature controllers, turbine air flow meters, orifice air flow meter, pressure drop gauges, energy consumption indicators, power indicators, weighing balance, oven, etc. are available. The laboratory is also extensively used for UG practical classes. |

|

College of Agricultural Engineering & Technology / Renewable Energy Engineering / PG Students

Ph.D. Students

| Sr. No. | Name | Admn. No. | Major Advisor | Title of Research |

| 1. | Iqbal Singh | L-2015-AE-111-D | Dr. Sukhmeet Singh | Development of Solar Energy Based Inclined Plate Honey Moisture Reduction System |

| 2 | Mohit Singla | L- 2016- AE- 124- D | Dr. V S Hans | Optimization of roughness geometry parameters of roughened evacuated tube collector solar air heater |

| 3. | Mahamed Mahmoud Mahamed El Wehishy | L-2020-AE-173-D | Dr S K Singh | Biodiesel production using Infrared and Ultrasonic techniques |